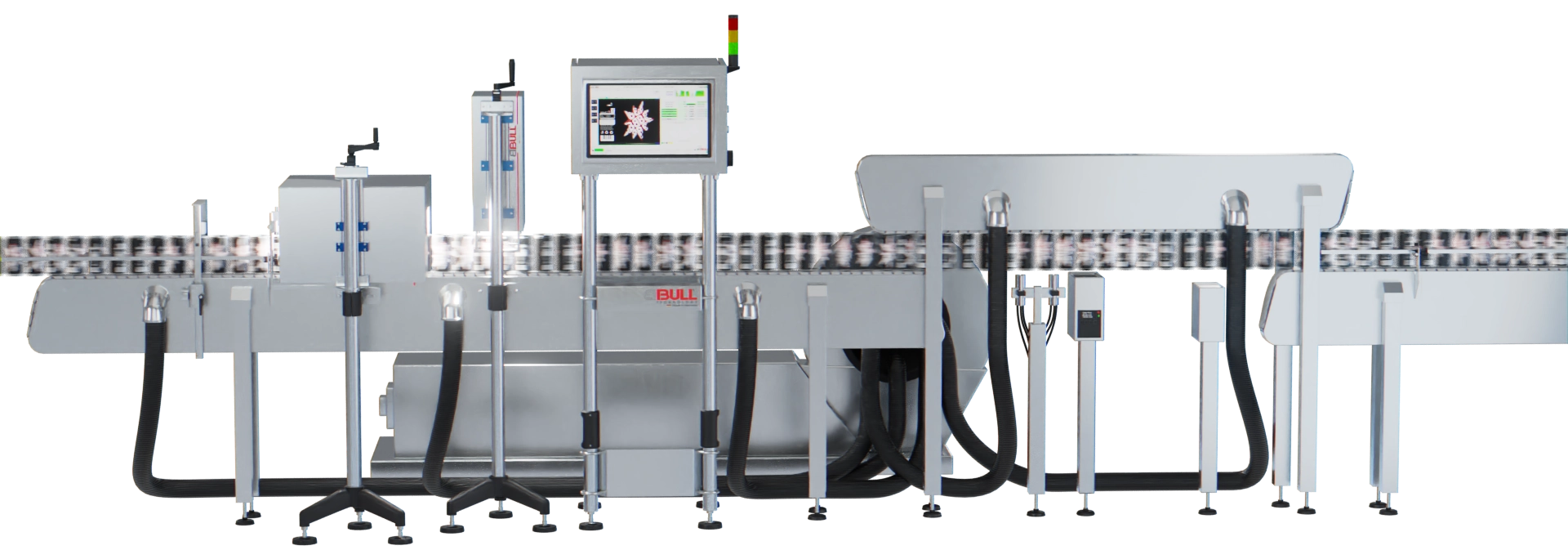

Herausragende Qualität & Effizienz. Mit Inspektions- & Ausleittechnik von BBULL Technology.

Ihr führender Partner im Bereich Kontrolltechnik.

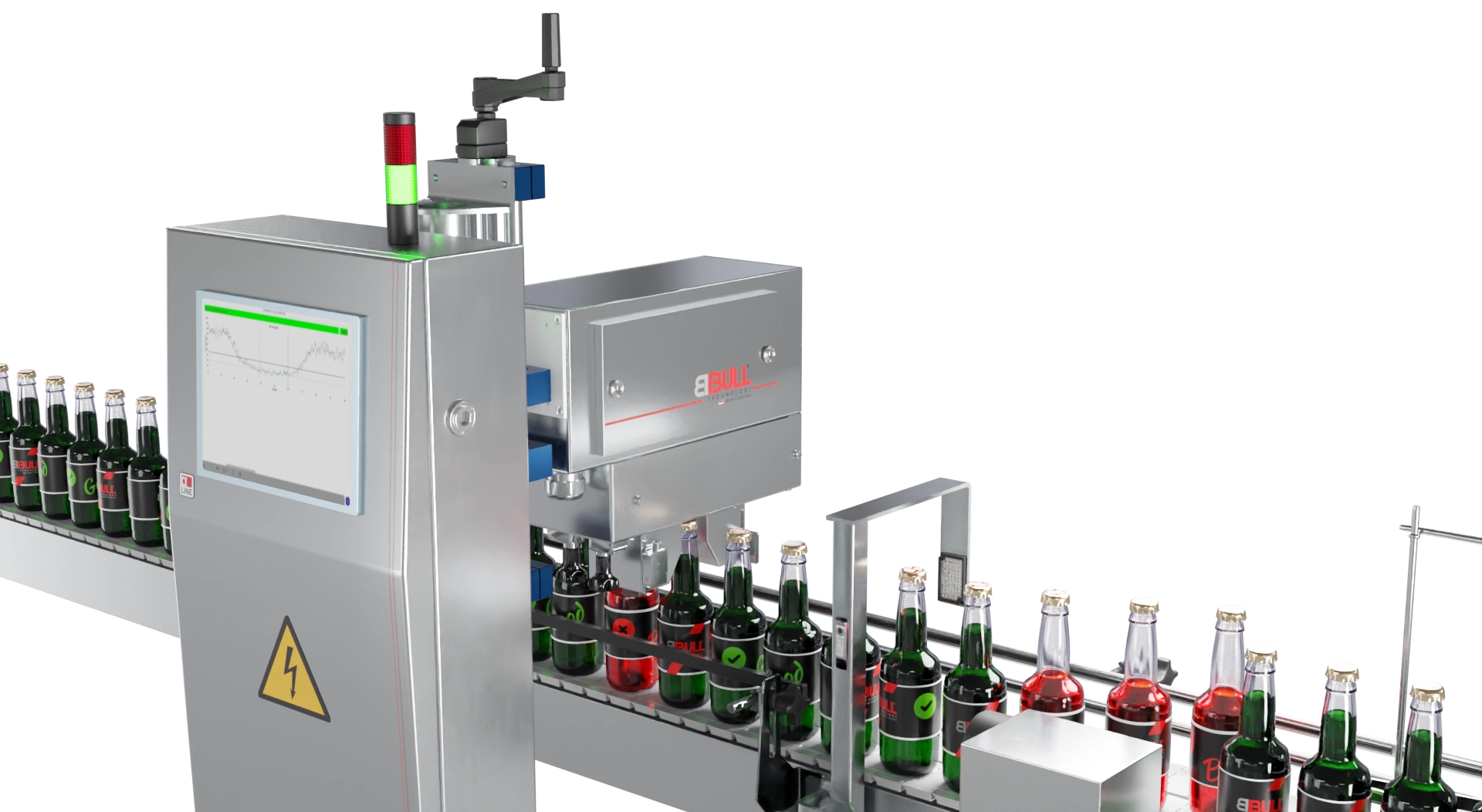

Wir bieten maximale Effizienz und herausragende Qualität durch unsere Inspektions- und Ausleitsysteme, perfekt abgestimmt auf jeden Behälter.

Entdecken Sie unser komplettes Produktprogramm und lassen Sie sich von unserer langjährigen Erfahrung und Expertise überzeugen. Mit unserem weltweiten Vertriebs- und Servicenetzwerk sind wir immer für Sie da, um Ihre individuellen Bedürfnisse zu erfüllen.

Werden Sie Teil unseres zufriedenen Kundenstamms und optimieren Sie Ihre Qualitätssicherung und Produktivität!

Entdecken Sie, wie Sie Ihre Qualitätssicherung und Produktivität mit unseren Inspektions- und Ausleitsysteme optimieren können!

oder

Wählen Sie einen Behältertyp

Sonstige Behälter

Tuben

Kanister

Wer wir sind

BBULL hat einen weltweiten Ruf als führender Hersteller im Bereich Kontrolltechnik.

Unser Erfolgsrezept:

Wir kombinieren das Wissen, die Erfahrung und den Ideenreichtum unserer Mitarbeiter mit zuverlässiger Inspektionstechnik – und überzeugen unsere Kunden mit den besten Produkten und Dienstleistungen bereits seit vielen Jahrzehnten.

Unsere Position als aktiver Partner der Getränke-, Lebensmittel- und Verpackungsindustrie möchten wir auch in Zukunft bewahren. Wir sind Teil unserer Kunden und übernehmen Verantwortung.

So befasst sich unser Team stetig mit Themen, die uns und unsere Kunden bewegen, und sucht nach Lösungen und Produkten, die ihre Qualitätssicherung und Produktivität verbessern. Wir überzeugen mit Wissen und Erfahrung und vertrauen unserem hoch motivierten und leistungsorientierten Team von Spezialisten, die für uns tätig sind.

Dadurch sind wir ein zuverlässiger Partner für zahlreiche Kunden und Auftraggeber. Und das ist die Basis für unseren Erfolg. Wir geben unseren Kunden die erwartete Sicherheit sowie die Gewissheit, dass unsere Produkte ihre Bedürfnisse erfüllen. Dafür stehen wir mit unserer Qualität und Technik. In Deutschland und international – und das seit Jahrzehnten.

BBULL TECHNOLOGY weltweit

- Software in über 25 Sprachen

- Weltweites Vertriebs- & Servicenetzwerk

- 24 Stunden Ersatzteilservice in den wichtigsten Märkten

- Beratung und Service in Landessprache

- Installation und Aftersales Service vor Ort

- Dokumentation in Landessprache

- Service und Montage durch Serviceabteilung

- Vorprojektierung im Haus, zur technischen Abklärung vor Auftragsauslieferung

- Komplettes Produktprogramm für Problemstellungen

- Einheitliche Soft- und Hardware Komponenten

- Einheitliche Bedienoberflächen

- Marktführer im Bereich Röntgen- & Ultraschalltechnologie

- Computerunterstützte Kameratechnologien zur Lösung kundenspezifischer Aufgabe

- Marktführer für kundenspezifische Verteil- & Sortiertechnik